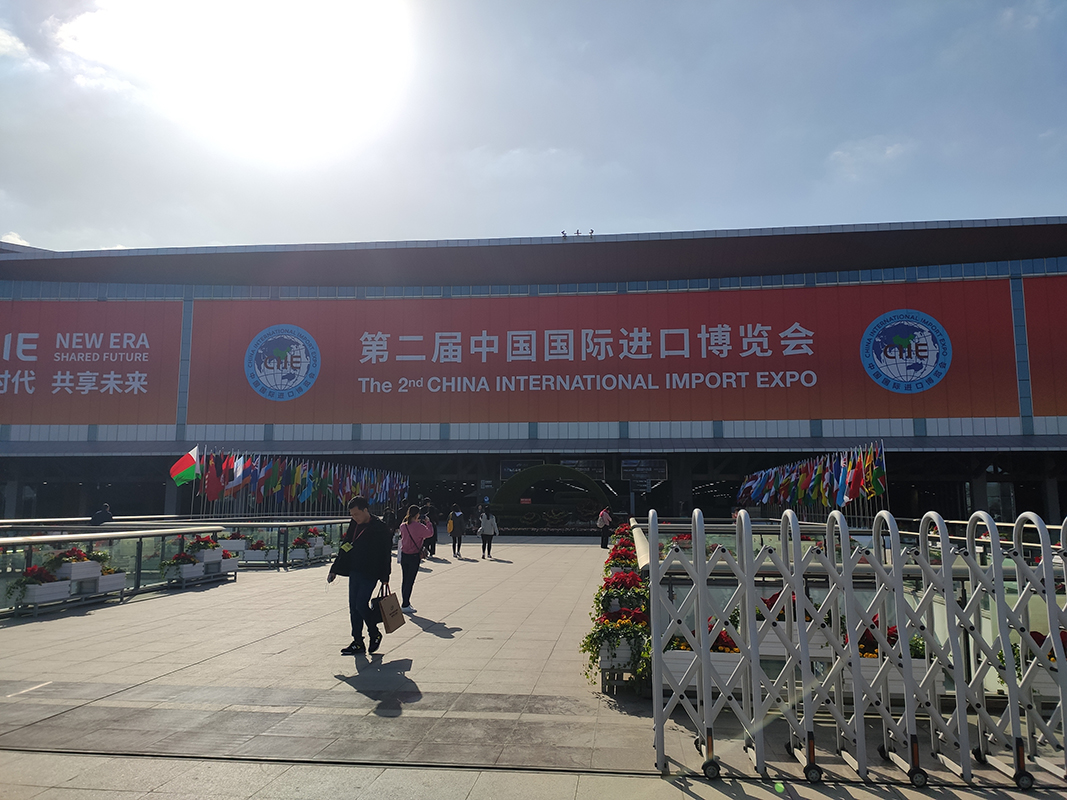

Our Exhibition

① in the production of puffing and sinking feed, the strong effect of extrusion should be weakened and the effect of conditioning should be enhanced.

In the production of expanded floating feed, it is necessary to strengthen the use of extrusion, and the material needs to receive strong shear force from the screw.

(2) low screw speed should be used for expanding sinking feed, which can not only provide the required extrusion shear effect, but also avoid high pressure, and avoid the sharp increase of material energy. The expansion after the die hole is too large to be sinking feed, while the expanding floating feed should adopt high screw speed.

③ the expansion machine is equipped with a steam exhaust and vacuum extraction device to open a pressure relief hole at a suitable position of the expansion cavity. In the production of floating feed, the pressure relief hole is blocked to meet the needs of high temperature and high pressure processing of floating feed; in the production of sinking feed, the pressure relief hole is opened to make the material reach the sleeve at the pressure relief hole, and the pressure is partially released. At the same time, some water vapor is also discharged from the pressure relief hole, and these materials are squeezed to the end of the expansion cavity, and the material is compacted to obtain a high volume weight sink Feed.