Brewing instant konjac rice, a new favorite for healthy eating!

Brewing instant konjac rice, a new favorite for healthy eating!

With the acceleration of the pace of life, convenient and fast food is increasingly favored by people. Instant konjac rice, as a new type of convenient food, is not only delicious but also rich in nutrients. This article will provide you with a detailed introduction to the ingredients, benefits, production equipment, and precautions of instant konjac rice, so that you can easily enjoy this delicacy at home.

Konjac rice: a perfect combination of deliciousness and health

Konjac rice, as the name suggests, is a new type of food that combines konjac with rice. It not only maintains the taste and aroma of rice, but also incorporates the nutritional value of konjac, bringing you a richer and healthier dietary choice.

High nutritional value: Konjac rice is rich in dietary fiber, various vitamins and minerals, which help promote digestion, lower cholesterol, control blood sugar, etc. It is an ideal food for maintaining physical health.

Low calorie and low-fat: Konjac rice has extremely low calorie and fat content, making it safe for even weight loss individuals to consume.

Convenient and fast: Simply brew and enjoy the delicious konjac rice, allowing you to easily maintain a healthy diet even in your busy life.

Konjac rice: production and processing technology

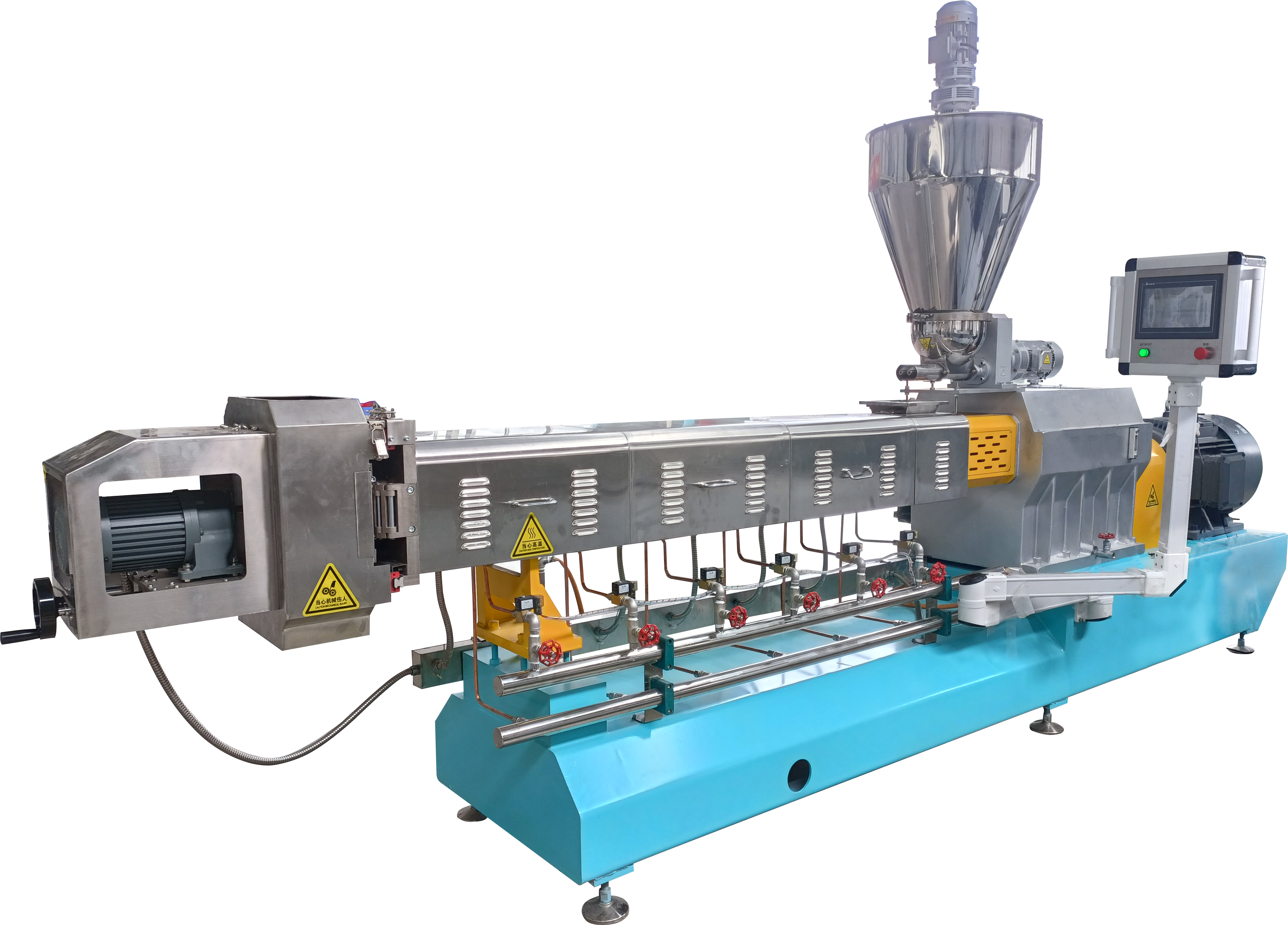

The production of artificial rice adopts twin-screw extrusion technology, which is composed of a feeding system, extrusion system, rotary cutting system, heating system, transmission system, and control system. Using screw extrusion technology, the material is matured and expanded into shape using high temperature and high pressure, and completed in one go.

1. Raw material processing: Konjac is processed to a certain fineness through screening, cleaning, and drying processes, and the granular raw materials are processed through a crushing system

2. Flour mixer: mix Rice noodles, konjak flour or other raw materials, add a certain amount of water, and fully mix well.

3. Vacuum feeding machine: Using the principle of vacuum for conveying, the mixed raw materials are transported to the feeding hopper of the extruder, ensuring convenient, fast, and pollution-free feeding.

4. Extruder: Matures materials in a high-pressure environment, extrudes rice particles, and adjusts the process and changes the mold to produce rice particles of different shapes.

5. Shaker screen: The extruded particles contain some temperature and viscosity, and are spread out through the shaker screen to avoid sticking together.

6. Air blower: Transport the product to the oven, and the height of the elevator is determined based on the oven.

7. Multi layer oven: The oven can be powered by multiple options including electricity, fuel, gas, and steam. The temperature can be adjusted between 0-200 degrees Celsius through the control cabinet. The interior is made of stainless steel mesh, and the baking time can be adjusted according to the speed to reduce particle moisture and increase shelf life;

8. Cooling conveyor: The dried particles contain a certain temperature and are cooled to room temperature to ensure packaging quality.

Artificial rice equipment has important application prospects in modern production and consumption. It can not only meet people's needs for nutrition, health, and deliciousness, but also bring new opportunities for agricultural production, improve the added value and market competitiveness of agricultural products. In addition, with the continuous development and improvement of artificial rice technology, artificial rice equipment will also have broader application prospects and become a new favorite in modern life

Company :

Address :

Phone :

Email :

Skype :

Whatapp/Wechat: