Decrypting the Large Double Screw Expander: A Sharp Weapon in the Food and Feed Processing Industry

Twin screw extruder

Double screw food pet feed puffing machine

Intelligent and efficient, advanced technology, and worry free after-sales service

Principle and working process

Large twin screw extruder is an important equipment in the food processing industry, playing an indispensable role in the food production process. This article will reveal the principle, application, and advantages of a large twin screw extruder, allowing us to explore this eye-catching industrial device together.

Puffing machine

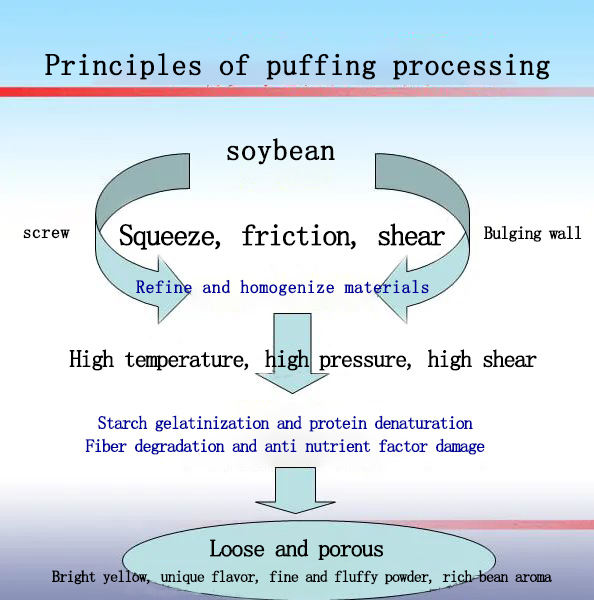

The large twin screw extruder adopts advanced extrusion technology to treat food ingredients under high temperature and pressure conditions. It mainly consists of two rotating screws, and through appropriate parameter settings, it can achieve processing processes such as puffing, gelatinization, and baking of food ingredients.

During the working process, after the ingredients enter the machine, they first pass through the preheating section to increase the temperature and make the ingredients soft; Next, it enters the expansion section, where due to the high-speed rotation of the screw and the high-pressure environment, the food rapidly expands and forms a porous structure; Finally, through the cooling section, the ingredients are solidified, the temperature is reduced, and the required product is obtained through shaping and cutting.

application area

Large twin screw extruders are widely used in the food processing industry, especially in the production of grain products and snack foods. It is often used to produce breakfast cereal, puffed rice cakes, puffed bean products, puffed snacks, etc.

This machine can not only process traditional ingredients, but also handle various ingredients and seasonings, achieving diversified product development. Its processing process is highly controllable and can meet the quality and taste requirements of different products.

Advantages and Value

Efficient production: The twin screw structure enables higher processing efficiency, which can significantly improve production efficiency and meet the needs of large-scale production.

Multifunctional operation: By adjusting parameters such as screw speed, pressure, and temperature, different ingredients can be processed and baked to meet the diverse product requirements.

Controllable product quality: An accurate and stable control system ensures the quality and taste of the product during the puffing process, providing a better consumer experience.

Energy conservation and environmental protection: Adopting advanced heating and cooling technologies, it can accurately control energy consumption and reduce the generation of waste and emissions, meeting the requirements of sustainable development.

The application of large twin screw extruder in the food processing industry is becoming increasingly widespread, bringing huge economic benefits and market competitiveness to enterprises. It not only meets the needs of modern people for high-quality and diversified food, but also promotes technological innovation and development in the food industry.

Large twin screw extruder, with its unique working principle and advantages, has become an indispensable tool in the food processing industry. It brings us delicious and diverse food choices through precise control and efficient processing. I believe that in the future development, the large twin screw extruder will continue to innovate and improve, bringing more surprises and opportunities to the food industry.

High strength screw/compression machine barrel/wear-resistant sleeve

Company :

Address :

Phone :

Email :

Skype :

Whatapp/Wechat: