Fast breakfast cereal production line

Fast breakfast cereal

Introduction to Breakfast Grain Production Line

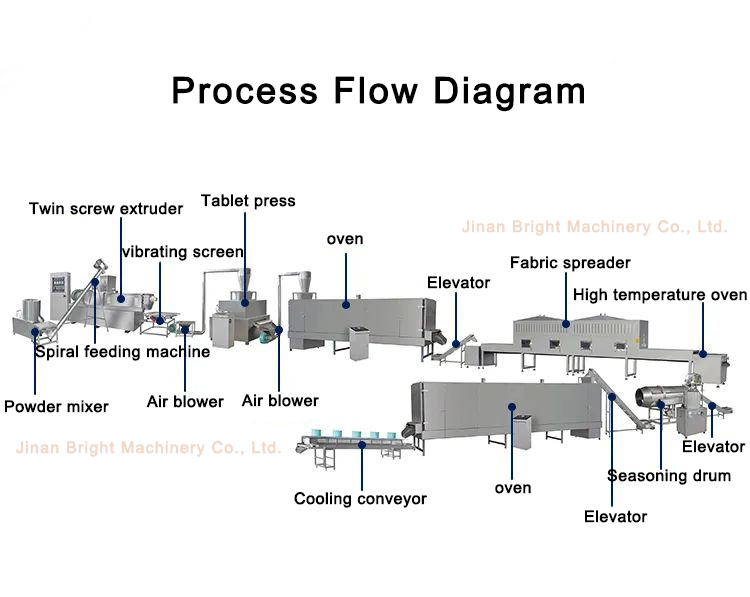

The breakfast grain production line adopts advanced puffing technology, which instantly puffs various grain raw materials into crispy and nutritious breakfast grains after high-temperature and high-pressure treatment. The entire production line consists of ingredients, mixing, puffing, drying, seasoning, cooling, packaging and other links, with high automation and fast production efficiency.

Production process analysis

1. Ingredients: The ingredients for corn flakes are very important. Seasoning should ensure a good taste, especially the requirements for corn raw materials, which directly affect whether high-quality corn flake products can be made, as well as the proportion and content of various nutrients.

2. Extrusion ripening molding: The extrusion ripening molding process of corn flakes is the key to producing high-quality corn flakes. Only in this way can dense, crispy, and fragrant corn flakes be made.

3 Cutting: Cut the material after being extruded and matured by a twin screw extruder into granular materials of uniform size, with the material appearing semi transparent.

4 Pre drying: The cut and formed materials enter the dryer for pre drying, and after drying, a certain tension is formed on the surface, which no longer adheres to each other, which is conducive to the smooth progress of tablet pressing.

Product sample display

5 Tablet pressing: The tablet pressing process is also a key factor in the production of corn flakes, with high requirements for the tablet press. The surface of the roller must have a high smoothness, and the roller must be kept at a constant temperature.

6. High temperature roasting: Whether the corn flake product has a hard, brittle, and dense organizational structure, highlighting the unique flavor of corn, and the roasting process is crucial.

7.After being roasted and cooled, the corn flakes are called corn flake products. Nowadays, many corn flakes are also processed in the post processing process, such as sugar coating, salt frying, or chocolate coating, which are mostly determined based on market taste.

8. After being sprayed with seasoning, the product is baked again to stabilize its shape, and after heat dissipation, it enters the packaging and packaging section

Product characteristic analysis:

Delicious and delicious: Breakfast grains processed with puffing technology have a crispy taste, a fragrant aroma, and a strong appetite.

Rich nutrition: The combination of various grain raw materials and nutritional ingredients makes breakfast grains rich in nutrients such as protein, vitamins, and minerals, meeting the nutritional needs of the human body.

Convenient and fast: The breakfast grain production line has a high degree of automation, fast production efficiency, and can quickly produce a large number of delicious and healthy breakfast grains.

Health and Environmental Protection: This production line adopts advanced puffing technology without adding any additives or preservatives, which is green and environmentally friendly, allowing consumers to eat with peace of mind.

Company :

Address :

Phone :

Email :

Skype :

Whatapp/Wechat: