"Magic Instruments" for Food and Feed Processing

In recent years, puffed food has become more and more popular among consumers due to its crispness and good taste. So, how are these delicious puffed foods produced? Originally, the puffing machine is a necessary equipment for puffing processing in the food industry.

Principle and classification of extruder

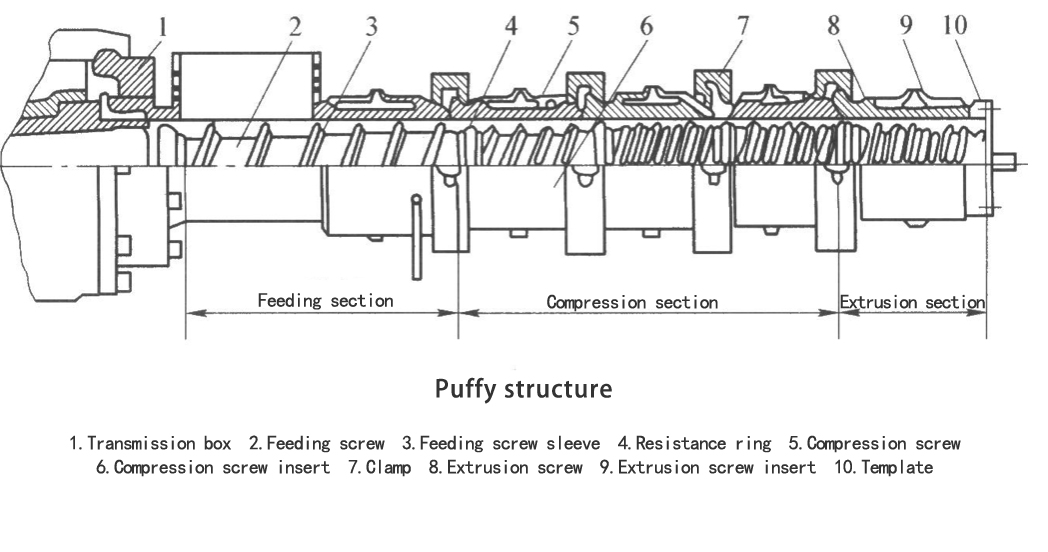

Extruder is a device that uses high temperature and pressure to extrude, deform, and sterilize substances. It is mainly composed of expansion pressure chamber, screw, electric control system, etc. According to different fields of use, puffing machines can be divided into food puffing machines, chemical puffing machines, pharmaceutical puffing machines, and feed puffing machines.

sample

Application of Extruder in Food Processing

Puffed food

The most common puffed foods are rice candy, popcorn, and cheese balls. In the extruder, processing materials such as corn and rice are expanded into porous structures through high temperature and pressure, achieving the effect of crispness and good taste.

Expanded soybean products

Expanded soybean products refer to foods formed from processed beans such as soybeans, such as soybean tissue protein, plant silk protein, and vegetarian meat protein. The bean raw materials can be matured and expanded through the extruder, making the food taste delicious, soft and delicious.

Feed application

The extruder can also be used for various aquatic feeds such as floating, sinking, buffering fish feed, crayfish feed, abalone and sea cucumber feed, and ornamental fish feed.

Advantages of Extruder in Food

1. To improve product quality, multiple raw materials can be processed: Twin screw extruder can simultaneously process multiple raw materials, such as raw materials in different fields such as feed, food, chemical, pharmaceutical, etc., with high applicability and flexibility.

2. Stable and reliable product quality: In a twin-screw extruder, the material is fully matured, resulting in a uniform distribution of internal temperature and even evaporation of water. These are conducive to ensuring stable and reliable product quality, with a better taste and taste.

3. High production efficiency: The screw in the twin screw extruder rotates rapidly, allowing materials to be fully mixed and matured, greatly improving production efficiency and making the production process more efficient.

4. Compact machine structure: The twin screw extruder has a compact structure, small footprint, and is convenient for installation and maintenance. In addition, the new twin screw extruder uses technologies such as a stabilized screw structure and a zero gap twin screw mechanism to effectively control the shear force, ensuring that all materials have the same maturation time and particle expansion coefficient in the extrusion cavity, thereby further improving product quality and production efficiency.

Internal details

Advantages of Extruder in Feed

Increase the nutritional content of feed: Twin screw extruder can use high temperature and high pressure to decompose starch molecules, making it easier for animals to absorb, and can also eliminate anti nutritional factors, improving the quality and taste of feed.

1. Enhance the digestibility of feed: The feed particles processed by a twin screw extruder are in a low density, porous flower shape, which is easy to be digested and absorbed by animals. At the same time, it is beneficial to enhance the solubility of feed, and is conducive to animal ingestion and absorption.

2. Improve feed stability: Using a twin screw extruder can achieve aseptic treatment of feed, thereby reducing the probability of feed deterioration, and maintaining the stability and consistency of feed ingredients.

3. Improve feed yield: Compared to other processing equipment, the twin screw extruder has a faster processing speed, improving feed yield and efficiency.

4. Convenient operation and maintenance: The twin screw extruder has a compact structure, convenient operation, and is easy to clean and maintain, greatly reducing the labor and material costs in the production process.