Power line maintenance and no-load debugging of extruder

Power line maintenance and no-load debugging of extruder

Turn on the power supply and test the operation

· Check the lubrication system. Start the "oil pump" start button (green), if there is oil in the oil pump overflow pipe, the oil pump will turn down, otherwise it will reverse. Open the upper cover of the distribution box and the side shield of the main engine to adjust the pressure of the pressure regulating valve and the throttle valve, check whether the oil is out of each sliding bearing, whether the lubrication point of the thrust bearing is normal, and whether the oil return is timely; run for 20 minutes, if the oil level does not Stop rising, then adjust the throttle valve.

· Check whether the interlock between the main motor and the lubricating motor is normal.

· Jog the main motor to check whether the spindle rotates forward.

· Jog the main motor and listen for abnormal noise in the distribution box and screw barrel.

· Turn the heating knob to the "ON" position to check the heating system. The normal heating current is 18-19A.

·Start the feeding motor, turn the speed regulating wheel, and check the operation and direction of the feeding screw.

·Start the rotary cutting motor, turn the speed control knob, and check whether the tool works normally.

·Start the main motor, from low speed to high speed, check whether the motor speed regulation system works normally.

At the initial stage of the pilot, it is planned to select areas with strong willingness to consume green power. After the pilot work of green power trading is launched, other willing areas will also give active support in the follow-up. During the pilot process, relevant departments will strengthen guidance, improve relevant supporting policies, coordinate and solve relevant problems in a timely manner, and create a favorable environment for green power trading.

No-load debugging

Other auxiliary equipment of the production line should also have a no-load test machine process to check the steering of the motor and whether there is any mechanical jamming.

load debug

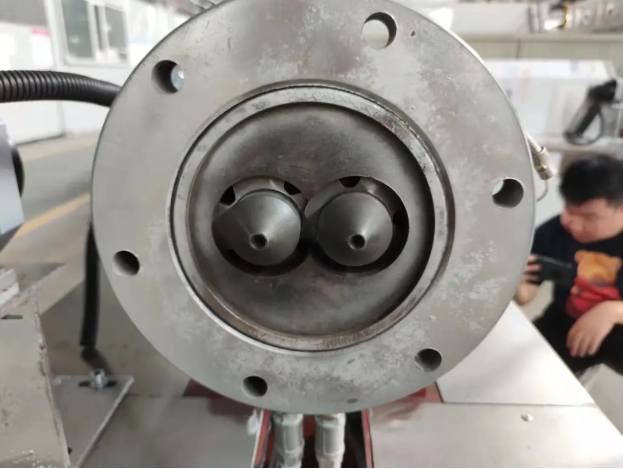

(1) After the no-load debugging is normal, install the die head seat and the used die head on the host.

※ The four nuts connecting the die must be fastened so as not to affect the discharge

(2) Preheating of the main engine: In order to stabilize the temperature in the barrel, a segmented heating method is adopted:

· Setting: 30°C in zone I, 100°C in zone II, 120°C in zone III, hold for 10 minutes

· Setting: 50°C in zone I, 140°C in zone II, 160°C in zone III, hold for 10 minutes

· Setting: 50°C in zone I, 160°C in zone II, 180°C in zone III, hold for 5 minutes

(3) While the host is preheating, the powder mixer can be operated to mix powder.

□ Mix 40kg of powder each time, and the powder should be evenly mixed, otherwise the puffing quality will be affected.

(4) After the temperature of the main engine rises to the set value, start the oil pump, and start the main motor after 2 minutes of oil supply. Turn on to 600 rpm (30Hz), add no less than 2000ml of water at the feeding port to facilitate discharging, start the feeding motor at the same time, and adjust the handwheel from slow to fast. If the discharging is normal, the speed of the main motor is gradually increased to 700 rpm (35Hz). The feeding amount is required to meet the needs of the main machine, and the material cannot be accumulated or empty. After feeding, the ammeter of the main motor should always be noted.

(5) After the material is normally extruded from the die head (no foreign matter and good puffing), start the rotary cutting motor, and then close the rotary cutting machine cover. Adjust the motor speed until the desired length and shape are cut.

(6) Before shutting down, add 1-1.5kg of raw materials with about 20% water content to facilitate cleaning and protection of the host.

(7) When stopping, first stop feeding, after about 3 minutes, the die head will no longer discharge, stop the main machine, after removing the die head, turn on the main motor, and add the puffed waste from the feed port until the exit is free of stickiness When the material is in the same state, it can be stopped, the die head can be cleaned, and the edible oil can be coated, and then loaded into the host for the next start-up.