Processing Technology of Sedimentary Aquatic Feed

Sedimentary aquatic feed

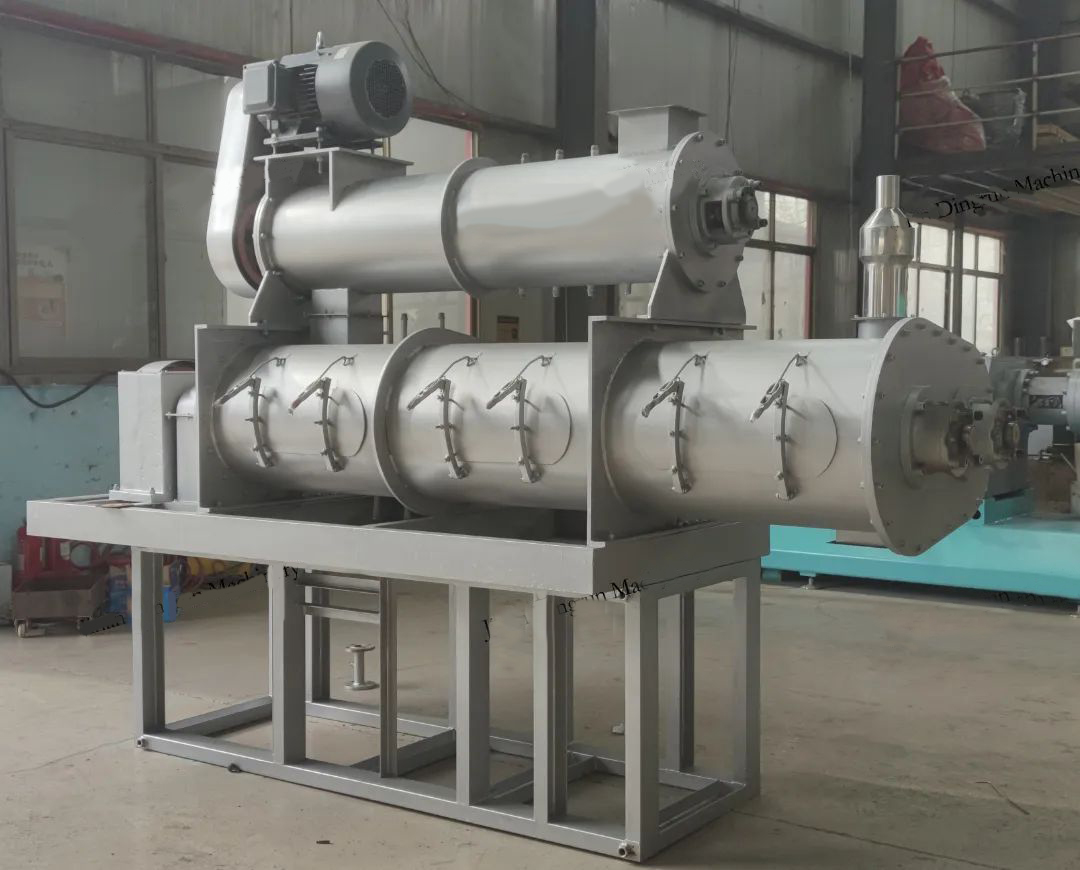

According to the feeding characteristics of different aquatic animals, such as benthic animals such as river crabs, they are accustomed to searching for food at the bottom of the water and adopt a slower feeding method. This way, the required feed particles cannot be too hard or too strong, and it is also necessary to minimize the loss of feed caused by small debris during the biting process. From this perspective, puffed sediment feed is more suitable: puffed sediment feed is easy to absorb water and soften, suitable for chewing, and can also reduce the loss of debris generated during chewing, reducing feed waste and water pollution. Moreover, the expanded feed has a long water resistance time and a high degree of maturation. Twin screw wet puffing machines are commonly used for producing puffed feed. There are many factors that affect the expansion of materials, but they are mainly closely related to the conditioning conditions, operating conditions of the extruder, and material properties. Changing the extrusion conditions can control the sinking and floating properties of puffed feed.

The importance of tempering

The role of conditioning is particularly important in the production of thickened puffed feed. When producing puffed sinking feed, it is necessary to weaken the strong squeezing effect and enhance the tempering effect. When tempering, add water and steam, and have sufficient tempering time to fully soften and ripen the material, creating conditions for the material to achieve better plasticity under weaker conditions in the expansion chamber in the next step. In this way, the material continues to ripen without producing significant swelling, resulting in a sinking feed. Adequate conditioning plays a good role in improving feed digestibility, product water resistance, and improving extrusion stability, i.e. product uniformity.

Screw shear

Expanded sinking feed should adopt a lower screw speed, which can provide the required squeezing and shearing effect without generating too high pressure, avoiding a sharp increase in material energy. After passing through the mold hole, the expansion is too large and it is not easy to become sinking feed.

temperature control

The control of chamber temperature is another important aspect of material energy control. In the feeding section of the extruder cavity, in order to ensure good conveying performance of the material, heating can be avoided; In the melting section of the machine cavity, heating must be carried out. The temperature of the machine cavity should be between 120 and 125 ℃, and should not be too high. The screw and the machine cavity act on shearing and kneading the material to promote material maturation and improve plasticity; At the homogenization section at the end of the cavity, cool the cavity (with a temperature of 40-50 ℃) to reduce the energy of the already matured plastic material, reduce the supersaturation of water in the material, and prevent excessive expansion when the material is extruded into the atmosphere through the mold hole.

The effect of swelling degree

The swelling degree of sinking feed is often less than 1.3, which can reach 2 or even 3 or more compared to floating feed. The pressure inside the machine cavity is related to the screw configuration of the extruder, material properties, template opening rate, and feed rate. The opening rate of the template affects the pressure of the material in the machine cavity. If the opening rate of the template is high, the discharge flow rate is large, and it is not easy to accumulate high pressure at the template. During trial production, the number of mold holes can be changed according to the situation to obtain suitable expanded and sinking feed.

Company :

Address :

Phone :

Email :

Skype :

Whatapp/Wechat: